The business of manufacturing investment castings is as old as time itself; however, even though the process of flowing molten metal to produce cast components used in machinery around the world is a well-established process, there also continues to be important developments in how the processing itself is carried out.

One of the most significant developments in recent history is the use of vacuum technology in the melting and pouring systems used to make exceptionally high-quality investment castings. The greatest tonnage of vacuum cast components is the crucial super alloy and titanium turbine blades spinning at a high velocity in the engines of aircraft carrying millions of people around the globe; however, the advantages of the process can be applied across a wide range of commercial castings as well.

What is Vacuum Casting?

Investment castings are generally produced in “air melt” alloys and environments, meaning that the metal is both melted and poured in a standard operating environment. However, some alloys, such as titanium and some high nickel super alloys require the absence of oxygen and other gases while the alloy is being melted and poured. These alloys must be processed in a vacuum to prevent reaction with these gases and the alloy at these high temperatures.

This highly specialized custom melting and pouring equipment allows for processing of these highly reactive metals to allow the investment casting manufacturer to be able to offer their highest quality castings in these unique alloys.

Types of Vacuum Investment Casting

Melting and/or casting under a vacuum requires the use of highly customized and specialized equipment designed for specific functions. Essentially, the general methodology of vacuum casting incorporates three main goals that the foundry wants to achieve, and how vacuum is utilized for each form the basis for each of these techniques.

The first two techniques are based on the theory that metal melted entirely under a vacuum is of higher quality due to its low gas content, resulting in near zero gas or inclusion porosity defects since the metal is melted from start to finish under a vacuum to eliminate all gaseous contaminants such as oxygen, nitrogen, and hydrogen.

The first technique is that the metal itself is melted under vacuum, and then the crucible containing the melted metal is removed from the vacuum chamber and poured in the usual atmosphere.

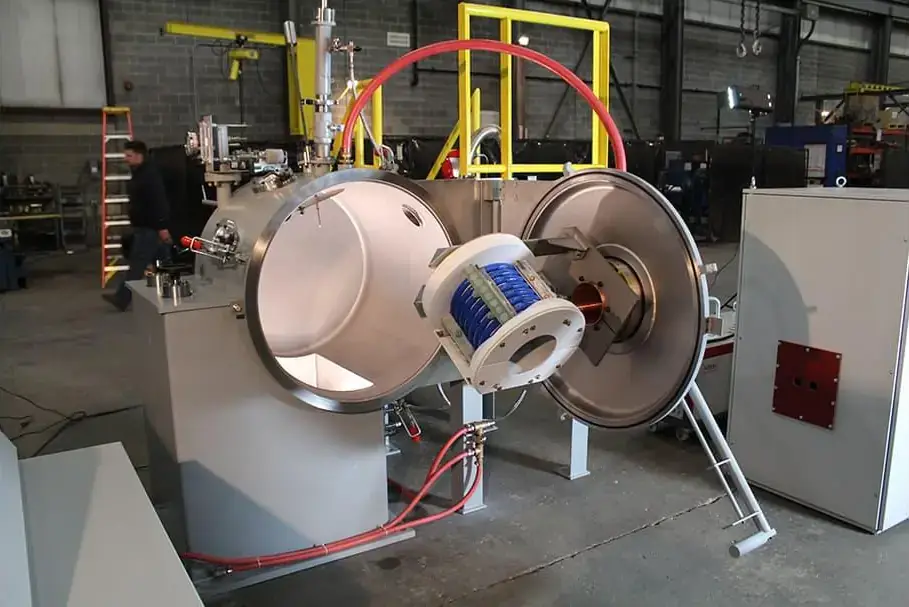

The second technique, and the most complex and costly to do, is to melt AND pour the metal into the ceramic shell mold while still under a vacuum, ensuring that the molten metal has absolutely zero exposure to the atmosphere, hence no chance to pick up any dissolved gases. This “dual chamber” technique is one which produces the highest quality castings possible due to their low gas content, however it is also an extremely costly method for producing castings and is reflected in the average $20,000 cost of a single jet engine turbine blade that is cast in this way.

The third application for vacuum casting does not necessarily involve melting under vacuum (however it could), but rather the vacuum is applied to the mold that is placed inside a vacuum chamber and the vacuum drawn to “pull” the molten metal into the mold quicker than can be achieved via gravity pouring, in one of a number of position orientations of the mold in relation to the source of molten metal.

This technique is used to form ultra-thin-walled castings that cannot be formed using conventional mold fill techniques. One well-known version of this vacuum casting technique is called the Hitchener Process, and actually involves the insertion of the top of the ceramic mold into the molten metal, which is still in the melting furnace.

Advantages and Disadvantages of Vacuum Casting

Advantages

The greatest advantage of vacuum investment casting is the enhanced quality and integrity of the investment casting over a gravity-poured-in-air method. The vacuum environment eliminates air and, as a result, eliminates the possibility of gas bubbles forming in the casting, resulting in parts with zero defects.

The vacuum process is particularly beneficial for producing thinner-walled castings and complex geometries with finer details than can generally be achieved with air melt and pour castings.

Finally, vacuum investment casting allows for the casting of metals that are prone to reactions with an oxygen rich environment, such as titanium and some of the nickel-based superalloys. The vacuum environment prevents oxidation during the casting process, ensuring the integrity of the castings compared with air melt.

Disadvantages

Despite its many benefits, vacuum investment casting also has one significant disadvantage over air melt/air pouring of investment castings, and that is the higher cost associated with the vacuum casting equipment due to the non-production-oriented equipment for the most part, and the complexity of the process.

Vacuum induction furnaces are expensive to set up and maintain, and this cost must be passed on to the customer, resulting in casting costs that are significantly higher than standard processing costs. Vacuum investment casting should be used only when necessary to achieve the required specifications.

In addition to the higher costs in using the process, the equipment needed for vacuum casting is generally more expensive and requires more maintenance than traditional casting equipment. This can be a significant issue for users of investment castings, particularly for small runs or customers with cost constraints.

While the costs for vacuum casting are higher, there are most certainly casting applications where design requires its use, and the highest possible quality in the casting is paramount. Vacuum investment casting offers a highly unique tool to the foundry to be able to offer this to the client.

What Alloys Can Be Vacuum Cast?

In theory, any alloy can be vacuum cast, and the benefits achieved are dependent on the alloy being cast. For example, melting and/or pouring a commonly melted stainless steel like 304 or 316 in a vacuum will ensure exceptionally low gas content; however, those alloys perform flawlessly in their intended application when melted in air, so the added cost of vacuum casting them to improve mechanical properties or corrosion resistance does not make sense.

However, some metals are highly reactive when melted in air (oxygen) and therefore cannot be melted in the presence of air. The most common of these alloys is titanium. Virtually all titanium castings are processed in the “dual chamber” type of vacuum furnace

Where an application demands superior mechanical properties at high temperatures, nickel-base superalloys should be vacuum cast. Vacuum investment casting protects the metal from the formation of oxides and nitrides that are deleterious to strength at high temperatures.

Vacuum Casting Super Alloys

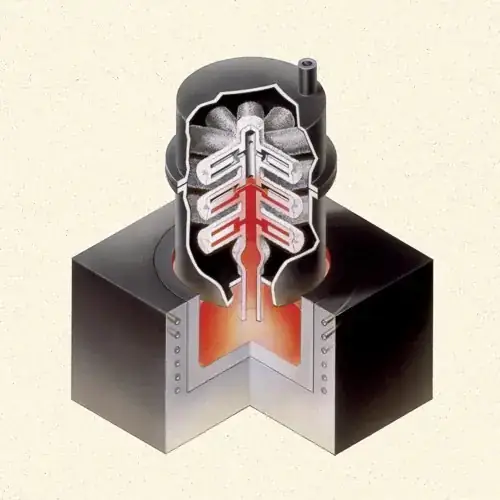

Nickel-base superalloys are typically used to achieve excellent strength at high temperatures. Many metals lose strength when heated; however, nickel-base superalloys retain their strength better than most alternative alloys. However, to cast a super alloy properly, the melting must be carried out under vacuum to avoid the formation of impurities such as oxides and nitrides, which would reduce its strength at high temperatures.

Super alloys also offer enhanced corrosion resistance. Corrosion resistance depends on the metal’s inherent ability to withstand adverse reactions with its environment. Nickel is inherently less reactive than metals like iron, so it is relatively stable.

Since some of the elements in a super alloy, such as chromium and titanium, react quickly with oxygen and other elements in the environment, vacuum melting these alloys preserves the content of reactive elements in the alloy and prevents oxidation losses and inclusions.

Casting Thin Walls in a Vacuum

One of the most significant challenges for manufacturers of investment castings is the ability to get molten metal to flow into tight spaces in the ceramic mold during the pouring process. These “tight spaces” generally represent “thin walls” in the casting design, and more often than not, the metal will start to freeze and solidify before it has the chance to completely fill the mold, resulting in misruns and cold-type defects.

However, with the assistance of vacuum technology, investment casting manufacturers can produce these types of thin-walled and highly intricate castings that would be difficult or impossible to achieve with the typical air melt and pour casting processes. Vacuum investment casting excels at allowing foundries to cast thinner walls, more intricate details, and sharper corners, resulting in overall higher quality castings.

Choose Niagara Investment Castings for Your Investment Casting Requirements

Manufacturing today requires resourceful out-of-the-box thinking to stay competitive in a global market. This mindset is what drives the skilled team at Niagara Investment Castings to be the best at what we can offer our clients.

Our planned future investment in the world of vacuum investment casting capabilities will offer our growing customer base another option for demonstrating how investment casting your components is a smart move today, as well as into the future.

As manufacturers like NIC integrate more technology into our plants to reduce costs, improve quality, and streamline deliveries, we are here to provide support in selecting the right investment castings for your specific application.

Please simply contact us here to start the discussion.