Solidworks

Niagara Investment Castings utilizes one  of the world’s leading CAD design formats … Solidworks. This technology allows us to be able to effectively communicate casting designs with our Customers, exchange design revision ideas, and even help our Customers during conversions by working with their old 2D designs and “building” and evaluating the casting with them on a computer screen before ever going to manufacturing. Solidworks allows us the freedom to work with the drawing files sent to us by our Customers no matter what other CAD design software they use. This ability to work with 3D CAD drawings not only ensures the fastest and most accurate and efficient quoting for our Customers, it enables us to offer the unique advantages of Solidification Modelling and 3D printed pattern prototyping.

of the world’s leading CAD design formats … Solidworks. This technology allows us to be able to effectively communicate casting designs with our Customers, exchange design revision ideas, and even help our Customers during conversions by working with their old 2D designs and “building” and evaluating the casting with them on a computer screen before ever going to manufacturing. Solidworks allows us the freedom to work with the drawing files sent to us by our Customers no matter what other CAD design software they use. This ability to work with 3D CAD drawings not only ensures the fastest and most accurate and efficient quoting for our Customers, it enables us to offer the unique advantages of Solidification Modelling and 3D printed pattern prototyping.

Solidification Modelling

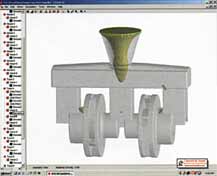

Niagara Investment Castings is pleased to offer our customers the value-added service of Solidification Modeling of their investment castings. This technology allows Niagara Investment Castings engineers to determine potential problem areas such as shrinkage or hot tears in a casting design before the casting is produced.

Niagara Investment Castings is pleased to offer our customers the value-added service of Solidification Modeling of their investment castings. This technology allows Niagara Investment Castings engineers to determine potential problem areas such as shrinkage or hot tears in a casting design before the casting is produced.

The heart of the technology is based on Niagara Investment Castings’s ability to work with 3D drawings, coupled with a PC based software program which simulates the pouring of hot metal of any alloy into the assembled virtual shell, and allows the metal to cool and solidify in real-time authenticity, revealing areas which will contain shrinkage or other heat related problems via visual indicators at the completion of the cooling of the castings. This approach is an extremely accurate way for Niagara Investment Castings to predict these problem areas in any casting design.

With this advance knowledge of potential problems, Niagara Investment Castings can work with the customer to revise, eliminate, or reduce design elements which may contribute to these types of casting defects, resulting in savings in time and costs. In addition, the critical decision of placement of gating can now be evaluated and tested without time consuming trial and error runs, resulting in more accurate costing, advanced knowledge of design changes required to facilitate gate placement, and overall casting quality improvement.

Please contact your Niagara Investment Castings Casting Specialist to learn how Solidification Modeling can help you achieve better casting results while saving costs.

3D Printed Pattern Prototyping

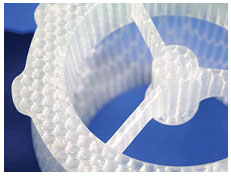

Niagara Investment Castings is pleased to offer our Customers the ability to have us “print” patterns from 3D CAD drawings in the same “lost wax” materials we would use on a production basis, and to then use those patterns to make a small run of samples or castings. This unique ability to take advantage of the surge in popularity of stereo lithographic printing gives our Customers the ability to test out a new casting design not as a plastic model, but as an  actual investment casting …. in the alloy, or alloys, of your choice, heat treated and fully functional … without the need or cost of building the injection tooling first!! Check out our page dedicated to this incredibly cost effective sampling technique here, or contact us now to learn more !!

actual investment casting …. in the alloy, or alloys, of your choice, heat treated and fully functional … without the need or cost of building the injection tooling first!! Check out our page dedicated to this incredibly cost effective sampling technique here, or contact us now to learn more !!

3D Scanning

Using the latest in infrared scanner technology, Niagara Investment Castings offers our Customers the ability to produce a digital scan of either a component to be replicated as an investment casting to produce a three dimensionally CAD drawing of the component, or to check the geometry of a casting that has been produced from a CAD file, to produce a “heat map” graphical dimensional report.