Niagara Investment Castings continues to transform how our clients can expand on the many advantages of the investment casting process. No longer are you restricted to using conventional wax patterns produced using hard tooling for R&D or short production runs. Our advanced rapid prototyping technology allows for the direct printing of three-dimensional plastic patterns from your 3D CAD data. This fast, tool-free alternative streamlines the creation of your investment castings, selecting from a wide range of alloys tailored to your specific needs.

Tailored Prototyping Solutions for Every Need

High-Quality SLA and Diverse Plastic Options

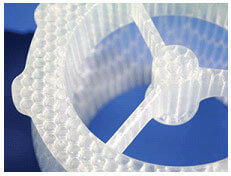

Dive into a world of precision with our high-quality SLA patterns and a versatile array of filament-type plastics. We’re equipped to custom-tailor prototype solutions that convey your design ideas and streamline short-run production projects. Experience the perfect blend of quality and customization to bring your visions to life.

Replicate Traditional Tooling with Enhanced Efficiency

Our rapid prototypes are replicas of what traditional tooling would yield without the associated longer lead times and expense of hard tooling, effectively removing those traditional constraints. Utilize our cutting-edge services to produce metal castings ready for evaluation and real-world application. Castings produced using 3D printed patterns match the quality and specifications of traditional wax pattern castings and are suitable for heat treatment, machining, and finishing according to your unique requirements.

Expand Your Design Possibilities with 3D Printed Patterns

Leverage our 3D-printed plastic pattern service to bring your new designs, conversions, or ideas to life without the initial investment in casting tooling. This service is designed to help you:

- Quickly prototype new designs and test their viability.

- Provide tangible cast samples for evaluating functionality, integrity, and performance.

- Discover cost-saving opportunities compared to machined forms, weldments, and assemblies.

- Facilitate clearer communication of concepts and designs within your team or to your clients.

- Accelerate the decision-making process with the fast provision of casting samples.

- Explore low-volume production options without the traditional investment casting overhead.

- Unleash your creative potential without any manufacturing constraints.

Transform Manufacturing with Niagara Investment Castings’ Rapid Prototype Casting

Discover the innovative realm of Rapid Prototype Casting (RPC) with Niagara Investment Castings. Bridging the crucial gap between digital design and physical reality, our services extend beyond traditional boundaries, embracing various materials through advanced CAD and 3D printing technologies. This marks a transformative shift towards agile, precise, and cost-effective manufacturing solutions tailored for the modern era.

The Modern Approach to Prototyping

Revolutionizing Manufacturing with RPC

Step into a new dimension of manufacturing where traditional methods meet modern innovation. Niagara Investment Castings’ rapid prototype casting technology integrates age-old precision with the speed of contemporary 3D printing technology, enabling the quick transformation of complex CAD models into tangible, functional prototypes. This strategic advantage is indispensable in sectors where reducing time-to-market is critical.

3D Printing and CAD Design Evolution

At Niagara Investment Castings, we leverage the latest in 3D printing and CAD to offer unmatched speed and accuracy in prototype development. This evolution allows for a diverse range of pattern materials that can be custom-tailored to meet your requirements and budgets.

Advanced Prototyping Techniques

Leading Innovations in Investment Casting

Our RPC advancements significantly improve traditional casting techniques. This enhances detail and turnaround, setting new industry standards.

Excellence in Investment Casting

Niagara Investment Castings’ RPC enriches investment casting by integrating 3D-printed patterns directly from CAD files, ensuring unprecedented precision and complexity in your prototypes. This innovation elevates the surface finish and detail, surpassing traditional methods and providing the adaptability required for iterative design processes.

Maximizing Benefits with RPC

Cost Efficiency and Unmatched Flexibility

Experience significant cost savings with our prototyping, especially for sampling and small production runs. Niagara Investment Castings offers a cost-effective solution, enabling the production of high-quality prototypes that defy the constraints of traditional manufacturing budgets.

Quality Evaluation and Optimal Design

Utilize our prototypes to perform comprehensive quality evaluations and design optimizations, identifying potential flaws and saving substantial resources before full-scale production. Early testing and validation produce a refined end product, ensuring market readiness and superior performance.

Gathering Crucial Market Feedback

Use our detailed prototypes to secure feedback from potential customers or stakeholders, providing critical insights influencing the final product design. This validation process is essential for aligning with market expectations and demands.

Exploring Design Versatility

Our RPC services empower you to test various sizes, intricate details, and finishes, rapidly determining the best design solutions and significantly shortening the development cycle.

Overcoming RPC Challenges with Niagara Investment Castings

A Fusion of Tradition and Innovation

Niagara Investment Castings harmonizes 3D printing with precise machining, offering prototypes that meet stringent quality standards. This combination ensures that every prototype is not just a concept but a near-exact replica of the final product, ready for rigorous testing and real-world application.

Frequently Asked Rapid Prototype Casting Questions

What is Rapid Prototype Casting (RPC), and how does it differ from traditional casting methods?

Rapid Prototype Casting is a modern manufacturing technique that utilizes 3D printing and CAD data to create precise, detailed prototypes quickly and cost-effectively. Unlike traditional casting, which relies on manual mold creation and can take weeks, RPC allows for producing prototypes in a fraction of the time without expensive tooling.

Can Niagara Investment Castings handle complex geometries and designs with their RPC service?

Absolutely! Our RPC service handles complex geometries and intricate designs that traditional manufacturing methods cannot achieve. With our advanced 3D printing technology and expert CAD design, we can create detailed prototypes that meet your requirements.

What materials can be used in Rapid Prototype Casting?

Our RPC process is versatile and can accommodate any of the same metals that you can traditionally cast using wax patterns.

How long does it take to receive a prototype using RPC?

The turnaround time for receiving a prototype can vary based on the complexity and size of the design, as well as the selected materials. However, RPC significantly reduces production time compared to traditional methods. Contact us with your project details, and we’ll provide an estimated timeframe.

Is RPC cost-effective for small production runs?

Yes, RPC is particularly cost-effective for small production runs. It eliminates the need for expensive tooling and molds, making it an ideal solution for producing high-quality prototypes or limited quantities of a final product without significant upfront costs.

Can I use RPC for functional testing and performance evaluation?

Prototypes produced through RPC are definitely suitable for functional testing and performance evaluations. They closely replicate the properties and characteristics of final production parts, allowing you to conduct comprehensive tests before moving to mass production.

What file formats do I need to provide for my design?

We typically accept CAD files in STL, STEP, IGES, and OBJ formats. If you have your design in another format, please get in touch with us to discuss compatibility and conversion options.

How does Niagara Investment Castings ensure the quality of prototypes?

We adhere to strict quality control processes and utilize state-of-the-art equipment to ensure that every prototype meets our high standards. Our team conducts thorough inspections and testing to ensure accuracy, durability, and performance.

Can Niagara Investment Castings assist with design modifications if needed?

Our engineers and designers can assist with any necessary design modifications to ensure your prototype meets all requirements and is optimized for the casting process.

What if I need a large quantity of prototypes? Is RPC still a viable option?

While RPC is most cost-effective for small to medium production runs, it can also be a viable option for larger quantities, depending on the specifics of your project. We recommend discussing your needs with our team to find the most efficient and cost-effective solution.

How can I get a quote for my RPC project?

Visit our “Request a Quote” page and provide details about your project, including CAD files, desired materials, quantity, and special requirements. Our team will review your information and get back to you with a detailed quote.

Embrace the Future of Manufacturing

As a pioneer in RPC, Niagara Investment Castings is committed to transforming your ideas into successful, market-ready products. Our cutting-edge services guarantee precision, efficiency, and a seamless transition from concept to production.

Niagara Investment Castings is your ideal partner if you’re ready to revolutionize your manufacturing process and bring your innovative designs to life. Start with us today to experience a streamlined, efficient path from concept to market.