The business of manufacturing investment castings continues to evolve from its earliest days of simple shapes molded in wax and coated in simple ceramics to produce a seamless high temperature mold able to withstand the tortures of molten metal alloys being poured into it to solidify and take the shape inside the mold.

Today, the modern world of producing investments casting is a primary example of how automation, AI, and complex data systems, can bring technology to bear on improving efficiencies, improving quality, and lowering costs, making a Canadian foundry like Niagara Investment Castings able to compete with anyone anywhere in the world.

In this article, we’ll dive deeper into the automation of the investment casting process, and the technologies that make it possible.

Automation In The Casting Process

Casting molten metal into solid geometric shapes is one of the oldest manufacturing techniques still in use today. Automation, including utilization of the latest technologies of computerization, robotics, artificial intelligence, and advanced machinery, allows modern foundries to enjoy higher quality, higher efficiencies, and reduced costs, while providing a safer and ultimately more desirable work environment for employees.

There are many components of investment casting automation which contribute to reaching these goals. These include:

- The utilization of robotics for what were previously labour intensive processes and operations

- Automated casting systems for more precise control of key operations in the investment casting process

- AI for effective simulation of casting processes to pinpoint problems well ahead of the actual production taking place

- SMART technologies for higher efficiencies in workflow from start to finish throughout the foundry

Robotics in Investment Casting

The investment casting process is a labour-intensive manufacturing process by its nature. This unique process involves the handling of wax patterns through a long and tedious “investing” operation to dip, or “invest” the wax patterns to form the unique ceramic shell that is the heart of the investment casting process.

These ceramic molds must be formed with exacting precision from one to another, to ensure there are no differences in how the molds perform, or how the metal being cast into them solidifies.

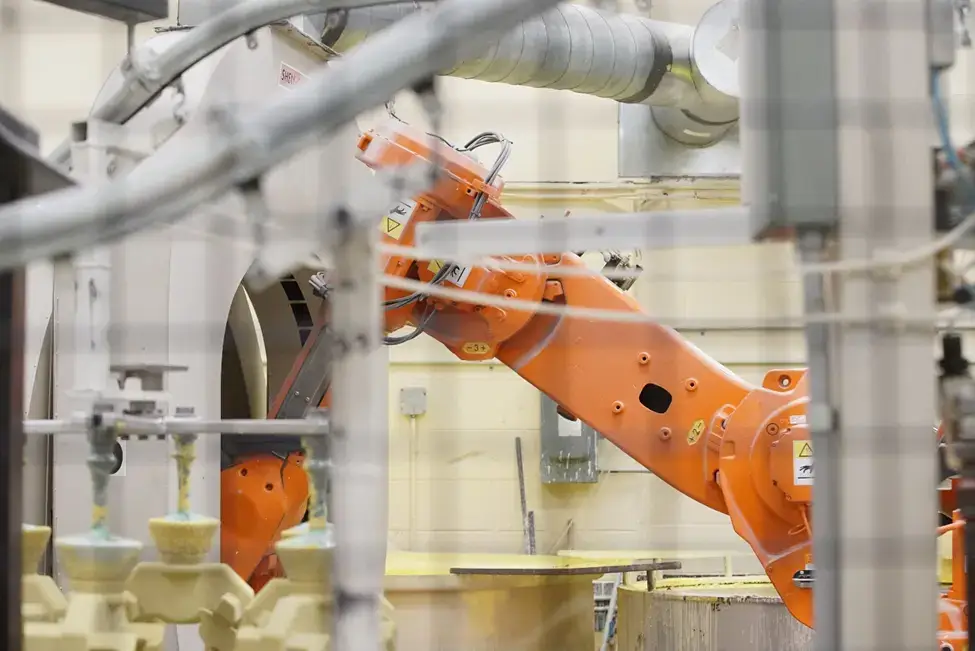

Once the castings are poured with the metal alloy and allowed to solidify, they need to get stripped free the ceramic mold material which is no longer needed, and the castings exposed for access to the gating so it can be cut through to separate the castings from the sprues.

Finally, since we produce investment castings up to 200 pounds in weight, the handling operations of the castings through finishing operations requires automation for efficient and safe handling of the castings.

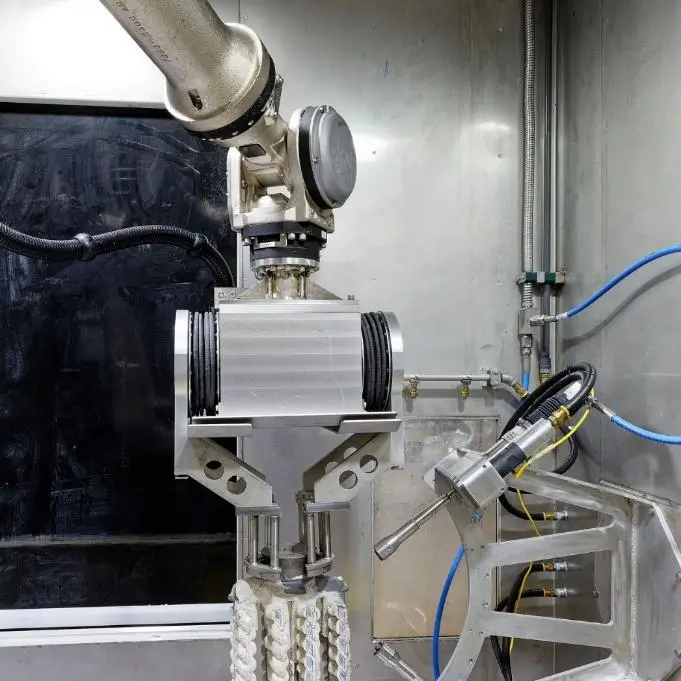

Foundries use these key manufacturing areas of our modern facility to achieve these goals. Robotic shell forming robots are designed and built for the critical application of shell forming through the dipping of the sprues into liquid ceramics and dry sand application machines including rainfall sanders and fluidized bed tanks, handling up to 6 trees, or sprues, at a time.

We are always working to find new opportunities throughout our plant to continue to utilize robotics in the handling of the castings through pouring to finishing operations such as grinding and cleaning, pattern production with automatic ejection, and assembly of these wax patterns to their respective sprues.

Automated Systems for Efficient and Safe Casting Production

There are many operations in the manufacturing of investment castings where reduction of labor cost is not ultimately as important as improving the efficiency of the process to aid in the best deliveries, and accuracy and repeatability to ensure consistent quality throughout.

With that in mind, the focus remains strong for finding opportunities to utilize automation where these goals are most critical throughout our facility.

From the initial operation of wax inject, to the finishing operations, automation can take many forms. Our goals of streamlining the overall flow through the plant, minimizing production time, optimizing conditions for the health and safety of our staff, and consistency to ensure the highest of quality.

These are some common automation techniques and technologies in investment casting:

- Robotics to handle the repetitive and dangerous tasks rather than requiring humans to perform these actions

- Mold drying lines to move the shells throughout the ideal drying condition for the layer of shell being added

- Automatic and semi-automatic wax injection tooling for the most efficient production and handling of wax patterns

- Mold handling devices to move shells in and out of 1,700 degree F furnaces in preparation for pouring

- Automatic grinding machines

- Laser guided cutoff saw

- State-of-the-art waterjet ceramic shell removal

Casting Process Control Automation and AI

Automation in the investment casting industry includes not only the physical handling advancements we utilize, but it also includes the many state-of-the-art modern technologies we count on to provide the highest quality possible in our cast products.

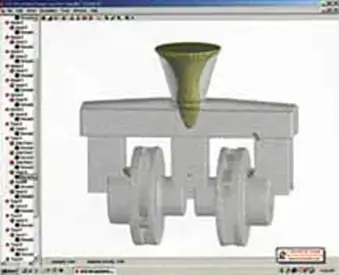

From 3D solidification modelling to predict the trouble spots in the engineering of a new casting project, to the 3D scanning of the finished castings to verify that the castings meet our clients stringent geometric requirements, these are only a couple examples of AI automation of our process controls which provide us with the data and information we need to produce consistently high quality investment castings in the shortest amount of time.

Choose Niagara Investment Castings for Your investment Casting Requirements

Manufacturing today requires resourceful out of the box thinking to stay competitive in a global market. This mindset is what drives the skilled team at Niagara Investment Castings to be the best at what we can offer our clients.

Our implementation of automation and artificial intelligence throughout our plant ensures your castings are manufactured on time and at the highest quality possible, all at globally competitive pricing.

Let us demonstrate how we can make our investment in automation work for you. Contact us to start the discussion!