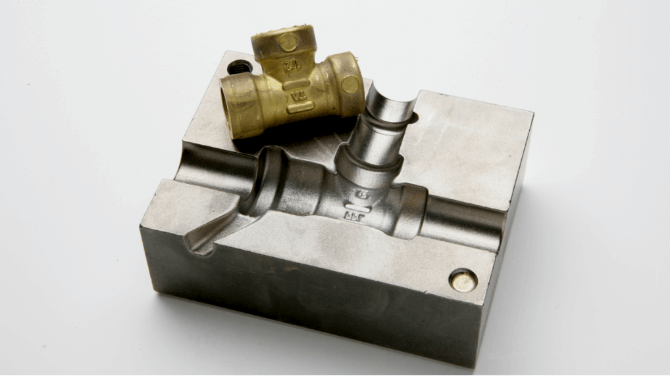

As the name implies, Niagara Investment Castings produces investment castings for a wide range of industries, and in a wide range of alloys. One of the lesser utilized families of steels that are cast however are the specially designed alloys known as “tool steels”.

Can Tool Steel Be Investment Cast?

Tool steels consist of carbon and alloy steels typically used for investment casting components for special applications where the more common steels would fail. These alloys are generally called tool steels because of their high hardness, wear resistance and abrasion resistance.

While highly useful for these purposes, one key characteristic of all of them is that they do not provide corrosion resistance, which should be taken into consideration. Tool steels include several different groups of alloys, each providing different levels of strength, surface hardness, toughness, working temperature and shock resistance.

Can Tool Steel Be Investment Cast?

Tool steels consist of carbon and alloy steels typically used for investment casting components for special applications where the more common steels would fail. These alloys are generally called tool steels because of their high hardness, wear resistance and abrasion resistance.

While highly useful for these purposes, one key characteristic of all of them is that they do not provide corrosion resistance, which should be taken into consideration. Tool steels include several different groups of alloys, each providing different levels of strength, surface hardness, toughness, working temperature and shock resistance.

Tool Steel Investment Casting Applications

Tool steels are exceptionally hard, tough, or wear-resistant alloys. Their properties come from both their chemistry and the subsequent heat treatments applied after casting. As their name intimates, these steels are capable of cutting, drilling, punching, hammering, and more. Tool steels are selected for a combination of the properties required to meet their application.

For example, a drill bit and a punch each need hardness and wear resistance. However, the punch experiences more impact while the drill bit experience more shear. Engineers and metallurgists pick the type of tool steel based on the tool’s use and will ask us to quote in the alloy which best meets all of the criteria.

In general, all tool steels have alloying elements that produce carbides, a densely packed metal lattice which contains a metal and carbon. Carbides are refractory material, which means they resist breaking down under pressure, chemicals, or heat. A tool steel also gets its hardness from precisely controlled heat treatment and quenching.

Tool Steels Typically Investment Cast

There are a group of the more commonly investment cast tool steel alloys which form the bulk of the alloys that are cast at Niagara Investment Castings. These alloys allow our clients to select the closest match to meet most every demanding application they require.

A-Grade Tool Steel Alloys

Air hardening, all-purpose tool steel with an increased chromium content. Provides good machinability, toughness and wear resistance. During production, these alloys are quenched in air. They have 0.05–2.85% carbon. These steels can contain up to 5% chromium. High chromium means that during heat treatment the A series won’t undergo dimensional distortion. Chromium produces closer tolerances. We offer the following A-grade tool steels for investment casting:

- A-2

D-Grade Tool Steel Casting Alloys

An air-hardening tool steel with a high chromium and carbon content for abrasion resistance. These cold work steels function up to 797°F (425°C). They contain 1.4–2.5% carbon and 11–13% chromium. They can be air or oil-quenched, depending on the alloy, and experience very little distortion in either cooling method.

These alloys generally have a very high abrasion resistance. These tool steel alloys retain their hardness at high temperatures and are ideal for investment casting cutting tools and dies. We provide the following grades of D-grade tool steels:

- D-2

- D-7

H-Grade Tool Steel Casting Alloys

Hot working tool steel with low carbon content and a chromium base. Provides hardness, abrasion resistance and the ability to withstand high-pressure applications. Hot-work tool steels all have a greater percentage of alloying elements to create more carbides and handle hotter working temperatures. Hot work tool steels can work in temperatures up to 1004°F (540°C).

As a group, most have low carbon percentages, below 0.6%. Hot work tool steel is often used in high-temperature manufacturing with malleable hot materials like metal and glass. Dies, stamps, extruders, and compressors all may be made with hot-work steel. The tool must continue to function even in extended heat exposure. We provide the following H-grade tool steels for precision investment casting:

- H-13

S-Grade Tool Steel Casting Alloys

These tool steels have a low carbon content and resist shock at low and high temperatures. S-grade tool steels also have high impact resistance but do not provide as much abrasion resistance as other grades. Shock-resisting tool steel Group S shock-resisting tool steels are incredibly strong, and built to have high impact resistance. Their strength does not simply lie at the surface or “shocked” layer of the tool. They may be used for springs, chisels, stamping dies, and punches. This group of alloys often has many alloying elements—most of which are seen in other tool steels. However, silicon, in the range of 0.15–3%, is present in this class of steels.

- S-1

- S-7

Choose Niagara Investment Castings for Your Investment Cast Tool Steel Applications

With decades of experience manufacturing high-quality investment castings, we are proud of our history of utilizing this unique manufacturing process to satisfy our clients requirements across a broad range of industries.

Our dedicated and experienced team at Niagara Investment Castings are here to help for any support in how investment castings made from these commonly used tool steels may just be the perfect solution for your component manufacturing.

Please simply contact us here to start the discussion!