The business of manufacturing investment castings remains a vital component in the cost-effective sourcing of metal components used in machinery worldwide. From simple pieces of hardware in everyday devices around us, to the crucial turbine blades in the engines of aircraft carrying millions of people worldwide, investment castings have found their place in today’s modern world after humble beginnings centuries ago.

While the investment casting process has stood the test of time, foundries utilize this unique process to take full advantage of its exceptional adaptability, combining it with the tools of today’s high-tech world. As a result, the future for investment castings is brighter than ever.

Let’s take a look at the future of investment castings, including what’s trending, what’s here to stay, and what to look forward to.

The History of Investment Casting

Investment casting as a means of manufacturing metal components can be traced back to the days of prehistoric artifacts being made by shaping beeswax and coating it with clay before the melted metal was poured into the mold. The first commercial use of investment casting began around the time of the Second World War, when a fast and dependable method of producing metal parts was needed.

Trends in Investment Casting

Today, there are investment casting manufacturers around the world operating in virtually every civilized country on every continent. Yet, with so much available manufacturing capacity, the potential for utilizing investment cast components in more and more applications remains strong and threatens to consume this available capacity faster than additional capacity can be brought online.

Key trends across all manufacturing include strong growth for the use of investment castings, driven by demands for cost-effective and efficient manufacturing in a wide cross-section of industrial sectors.

Typically, strong acceptance has been in the aerospace, automotive, and energy production industries; however, more and more sectors are finding the unique benefits of design freedom and low cost to be ideal for applications in a wide range of industries, and over a growing range of metal alloys that can be successfully investment cast.

Will Investment Casting Replace Other Manufacturing Methods?

This growth in the utilization of investment castings is a direct result of renewed interest in the process thanks to both the expansion of education in todays high schools, colleges, and trade programs with the young engineering workforce about the benefits of investment castings, along with the evolution of technologies that will allow manufacturers like NIC to compete with investment casting manufacturers around the world, including China and India.

This is something that has never been so predominant as it is today, and this will lead to ever-increasing growth for the use of investment castings to replace other manufacturing methods, including :

- Assembling two or more separate pieces into a single casting;

- Investment casting of parts that are typically machined from a generic shape, such as a bar, block, or plate, by investment casting to eliminate or minimize machining;

- Forgings to take advantage of the higher detail attainable in an investment casting;

- Sand castings to take advantage of the smooth surface finish and high dimensional accuracy of the investment cast process

While there are many benefits to utilizing investment castings, our industry also faces challenges that form obstacles to an easier path forward and a more universal acceptance of the process. Some of those challenges are as follows:

- High initial costs. Investing in setting up a modern facility for investment casting, including the necessary automation and advanced technologies, requires substantial initial capital, posing a barrier for smaller manufacturers.

- Raw material volatility: Fluctuating prices and supply chain disruptions for metals and alloys can impact production costs and profitability.

- Skills gap: As foundries become more digital and automated, there is a growing need for skilled workers trained in advanced casting technologies.

- Regulatory pressure: Increasingly stringent environmental regulations require costly upgrades to meet compliance standards.

Key Investment Casting Technologies for the Future

There are continuously emerging trends and technologies in investment casting that are designed to enhance the efficiency and cost-effectiveness of the process while expanding its capabilities. By leveraging these trends and technologies, Niagara Investment Castings can meet the ever-changing demands of a diverse range of industries and remain competitive in today’s and future global markets.

Additive Manufacturing

Additive manufacturing, also known as 3D printing, is being increasingly integrated into the investment casting process. This ever-evolving technology enables the direct production of complex wax patterns, thereby eliminating the need for traditional pattern-making methods. This enables the foundry to produce low-cost prototypes without the need for production tooling.

Advanced Materials

The use of advanced materials in investment casting is one way manufacturers, looking for ways to reduce costs, can take advantage of the “near net shape” characteristic of investment casting. High-performance alloys are being developed and utilized to meet the increasing demands for specialized applications in industries where enhanced strength and temperature resistance are essential.

Simulation and Modelling

Computer simulations and modelling techniques are becoming more sophisticated and accurate. Our casting simulation software enables the prediction of casting defects such as shrinkage, and this helps optimize the casting process, reduce costs, and improve overall part quality.

Automation and Robotics

Automation and robotics are key to being employed to streamline various stages of the investment casting process. Robotic systems can be utilized effectively for pattern assembly, shell building, and finishing operations such as grinding of gates. Automated systems enhance precision, consistency, and productivity while reducing human error and injuries from lifting and bending.

Digitization and Data Analytics

Digital technologies and data analytics are playing an increasing role in investment casting. Sensors and monitoring systems are used to collect real-time data during the casting process, enabling proactive quality control and process optimization. Data analytics help identify patterns, trends, and potential improvements for enhanced efficiency and quality.

Advanced Quality Assurance

Non-destructive testing (NDT) methods, such as X-ray and liquid penetrant testing, are being further developed to ensure the integrity of castings. These vital inspection techniques provide enhanced detection of defects and improved quality.

Green and Sustainable Practices

Environmental considerations have become critical in the investment casting industry. Sustainable practices, such as the use of eco-friendly materials, energy-efficient processes, and waste reduction, are being increasingly embraced to minimize the environmental impact of the investment casting process.

The Next 10 Years in Investment Casting: What to Expect

Investment casting manufacturing plants are located worldwide. However, a few manufacturers dare to think “outside the box” to design and build the best facilities for manufacturing investment castings, utilizing machinery, technologies, and process innovations that set a new threshold for excellence in quality and efficiency.

Niagara Investment Castings is proud to be part of a team of foundries and foundrymen who are always looking for the next great idea to set us apart from the competition. We are excited about what the next ten years may bring as we strive to be the quality-first, cost-effective leader in the manufacturing of investment castings for our clients worldwide.

Some of the out-of-the-box planning we are pursuing includes the following leading-edge technologies already available to our business:

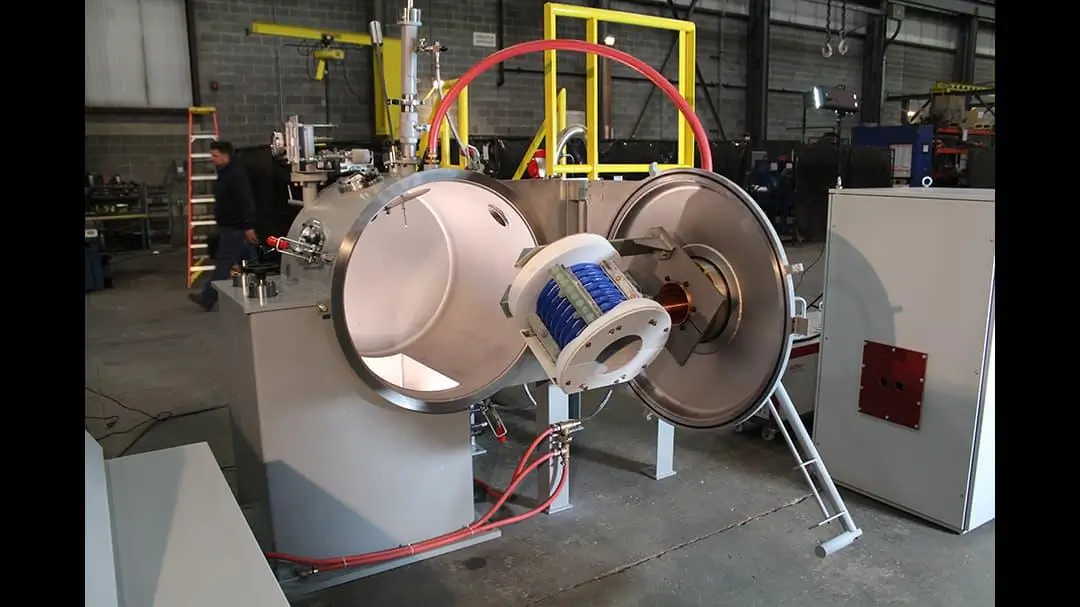

Vacuum Melting and Pouring

Investment castings are generally produced in “air melt” alloys and environments, meaning that the metal is both melted and poured in a standard operating environment. However, some alloys, such as titanium and certain high-nickel super alloys, require the exclusion of oxygen and other gases during the melting and pouring process.

These alloys must be processed in a vacuum to prevent reaction with these gases and the alloy at these high temperatures. This highly specialized custom melting and pouring equipment enables the processing of these highly reactive metals, allowing the investment casting manufacturer to offer its highest-quality castings in these unique alloys.

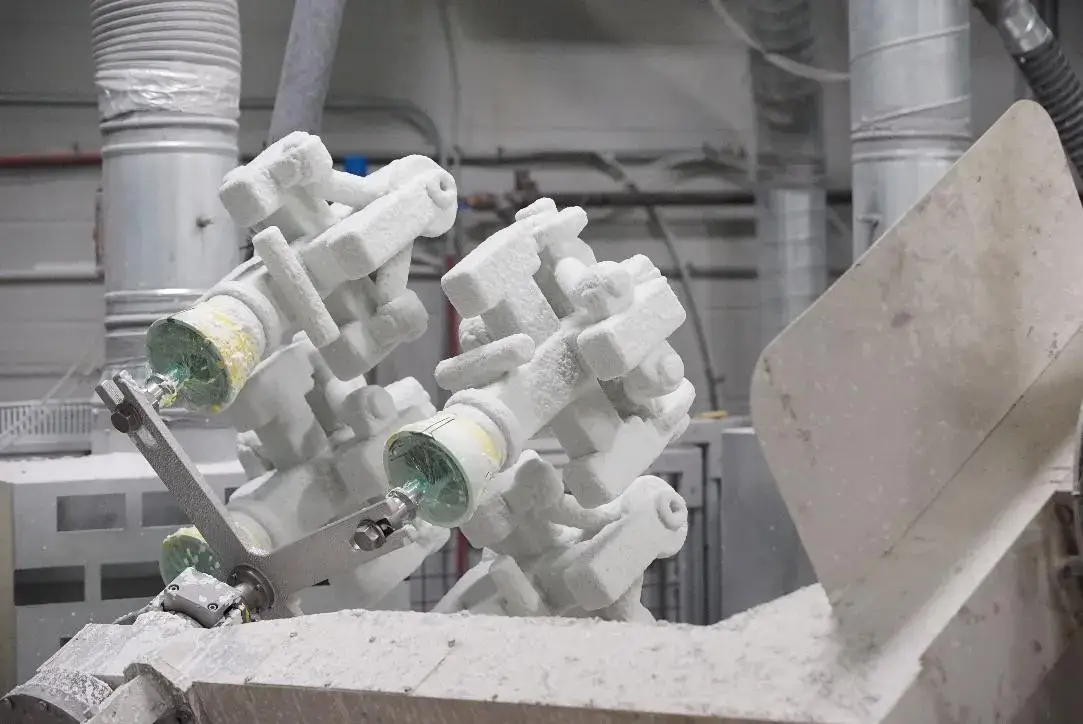

Robotics

The use of robotics for the manufacturing of investment castings is virtually limitless. From the assembly of the patterns to the sprue to the precise finish grinding of the castings’ gating systems, robots offer cost efficiencies, repeatable and consistent results, and around-the-clock production. Not only are costs and efficiencies improved, today’s multi-axis robots can lift more weight, move faster, and don’t call in sick, when compared to a human worker.

The increasing use of robotics in a state-of-the-art investment casting facility will always be the frontrunner in determining how best to utilize innovation and out-of-the-box thinking when envisioning the foundry’s technology advancements over the next 10 years.

No Tooling Required Pattern Production

The developments behind additive manufacturing are among the fastest-evolving technologies today, and investment casting manufacturers are increasingly incorporating this technology into their operations.

One of the most exciting developments is the cost of production of 3D printed disposable patterns coming down; at the same time, the efficiencies of the 3D printing process are improving markedly. This presents an unprecedented opportunity to change the status quo of how patterns are produced, as companies like NIC are using 3D printing to print production patterns in wax or plastic, rather than relying on expensive and time-consuming dies to inject wax into them.

These disposable patterns function exactly like the injected wax patterns that are typically used; however, they are lighter, less expensive to produce, and can be made by machines unsupervised 24 hours a day.

3D Printed Ceramic Molds and Cores

3D printing, also known as “Additive Manufacturing,” is one of the most valuable tools available today to investment casting manufacturers. While Niagara Investment Castings utilizes this technology today for pattern production, the sky is the limit, as manufacturers of these printers have started to produce 3D printing machines that can print directly in ceramic materials, bypassing the need to produce the disposable pattern altogether. The ceramic mold itself can be 3D printed, ready to be fired and poured within hours rather than the weeks it can currently take.

3D printing of ceramic molds is one of the most consequential evolving technologies that will undoubtedly impact how investment castings are produced in the future.

Choose Niagara Investment Castings for Your Investment Casting Requirements

Manufacturing today requires resourceful out-of-the-box thinking to stay competitive in a global market. This mindset is what drives the skilled team at Niagara Investment Castings to be the best at what we can offer our clients.

Let us show you how investment casting your components is a smart move today, as well as well into the future, as manufacturers like NIC bring more and more technology into our plants to reduce costs, improve quality, and drive deliveries down. We are here to provide support in selecting the right investment castings for your specific application. Please simply contact us here to start the discussion.