One of the greatest opportunities for taking advantage of the flexibility, quality, and cost effectiveness of investment casting is in the manufacturing of components used in the energy industry.

Investment castings of all shapes and sizes are found in the demanding applications for power generation, in the oil patch, and for renewable energy, the all-important buzzword of the 21st century.

Investment castings offer intricate geometries, high quality internal integrity, and high levels of precision, all characteristics of the kinds of crucial components that are used in abundance in an industry that demands metal parts that must withstand harsh environments and perform reliably for extended time periods, often well below, or above, the surface of the planet.

Investment Castings for the Oil and Gas Industry

Niagara Investment Castings produces a wide range of investment castings that are utilized in a wide range of applications related to the critically important oil and gas industry, sometimes referred to as the supply side of the petrochemical business.

From exploration, drilling, and management of fluids and gases, strong investment cast components ranging from heat treatable steels, stainless steels and nickel based superalloys, to the unique strength and wear properties of cobalt based alloys, are used extensively all over the world to build the equipment needed to extract vital minerals from the earth.

The investment casting process offers an unlimited number of possibilities when designing components for petrochemical applications, and as a result there is a wide range of components used in petrochemical engineering.

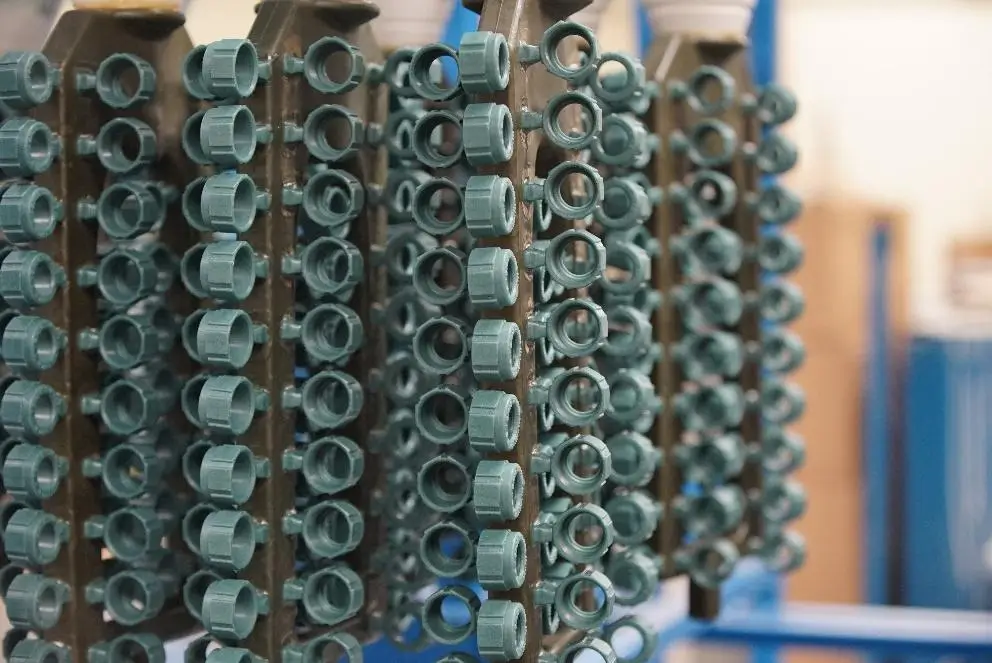

For example, valves control the flow of fluids and regulate the movement of gases, liquids and hazardous substances. Pump impellers efficiently move the fluid through a series of pipes, pressure regulating equipment, flow control devices, and safety equipment, all made from robust corrosion and chemical resistant cast materials. Pipe fittings seal and support the vast network of pipelines around the world, and most of these crucial components are castings.

Cobalt wear resistant components are critical to the check valves that are utilized in jack pumps around the world. A wide range of pumps facilitate fluid transport throughout the petrochemical infrastructure. Fittings and connectors enable seamless integration of various components. Structural components lend strength and heat resistance to components that need to stay strong through extreme high temperatures.

Investment Castings for the Wind and Solar Industries

The investment casting process is heavily utilized to produce a variety of components found in renewable energy equipment, especially in todays wind turbines.

Cast components from a fraction of a pound, up to 200 pounds, are efficiently investment cast to take advantage of the design freedom and high quality that is required for highly engineered high strength components that must perform in extreme conditions.

Niagara Investment Castings produces castings in a wide range of alloys that suit the wind and solar industry, and because the design of many parts of todays wind turbines is an evolving process, many engineers and designers will take advantage of our prototyping services to evaluate new designs before committing to the cost for production tooling.

The green energy industry is heavily focused on sustainability, and the investment casting process can be depended on to produce cast components that use minimal energy and produce minimal waste in the manufacturing of a multitude of parts in a wide range of alloys from steel to aluminum.

Investment Castings for Nuclear Power

There are many parallel advantages of using investment castings for the nuclear industry that are the reason they are so predominantly utilized in the petrochemical industry. Crucial applications for the nuclear industry demand the highest quality of components, especially in this industry where failure is not an option.

Investment casting is used to efficiently manufacture components with intricate shapes and complex internal geometries, typical for parts used in the nuclear industry. Many nuclear reactors utilize thousands of the same components throughout their design, and investment castings offer the ability to have a high level of accuracy and repeatability from part to part.

Non-destructive testing of investment cast components ensures the highest level of quality for these critical application parts, ensuring defect free castings are utilized in some of the largest nuclear projects ever developed.

Casting integrity is key, and Niagara Investment Castings offers a wide range of these NDT inspection services as well as chemical analysis, metallurgical examination, and strength testing of the cast metal, to ensure the castings will perform flawlessly in their intended role, safeguarding the health and safety of the people who will be working with these crucial sources for cost effective energy around the globe.

What Energy Components Can be Investment Cast?

There are many reasons why manufacturers worldwide choose investment castings to produce the many types of components used in the energy industry. Some examples of those components are as follows:

-

Lifting Lugs

-

Downhole check valves

-

Completion parts

-

Drilling components

-

Elbows and Tees

-

Pump parts

-

Valve bodies, discs, and sealing components

-

Bifurcates

-

Catalyst Plates and cones

-

Reducers

-

Furnace tubes and components

-

Hangers and mounts

-

Mounting hardware for solar panels

-

Wind turbine blade hardware and fasteners

-

Wind turbine brake components

-

Guides

-

Pins

-

Recuperator components

-

Tuyeres

-

Riders

-

Grids

-

and much, much more

What are the Advantages of Investment Castings for the Energy Industry?

Design Freedom

There are virtually no limits to the design, complexity, or functionality of investment castings. Internal detail, simple or complex, can often be cast where traditional machining cannot be utilized.

Alloy Selection

Niagara Investment Castings offers a full range of alloys for virtually every application in the energy industry. From high-strength steel, corrosion-resistant stainless steels and heat-resistant nickel alloys, to non-ferrous-based alloys including wear-resistant cobalt and highly versatile copper-based alloys, there is nothing we cannot work with to meet your requirements.

In addition to a wide range of alloys, Niagara Investment Castings will ensure the correct metal heat treatment is applied to the casting to ensure maximum strength and corrosion resistance.

Dependable and Consistent

The investment casting process delivers components with unmatched repeatability from part to part in a cast component, often allowing the component to avoid costly finishing processes such as machining.

The smooth surface finish of the investment casting allows for unimpaired fluid movement through the many cast components in the pumps, valves, and piping that make up a large part of the equipment used in the energy industry.

Cost Effective

The low-cost benefits of investment casting the multiple parts repeatedly used in energy-related equipment are well known among the leading manufacturers of energy equipment around the world.

The ability to use a single wax injection tool to produce tens of thousands of wax patterns to produce castings with incredible consistency is why designers turn to Niagara Investment Castings to manufacture their many critical application components using the investment casting process.

Let NIC Help You with Manufacturing Your Energy Components as Investment Castings

With decades of experience manufacturing high-quality investment castings for a multitude of energy-related customers, we are proud of our history of utilizing this unique manufacturing process to satisfy our clients’ requirements for crucial parts across a broad range of industries.

Our dedicated and experienced team at Niagara Investment Castings are here to help you show why investment casting is the perfect solution for your component manufacturing.