Niagara Investment Castings produces commercial-quality investment castings, as well as upgraded castings for more stringent applications.

Metal testing and certification is a crucial step in the assuring of quality, reliability, and conformance for the metal used to produce investment castings. These processes include the wide ranging series of tests and inspections that are acceptable to most modern industries to verify that the cast metal meets the rigorous requirements of the intended application for the castings.

Niagara Investment Castings can provide all levels of metal material testing and inspection to verify quality and certify our investment castings to meet your strict requirements, from a simple and thorough visual examination to today’s latest non-destructive testing methods.

Metal Material Testing

Niagara Investment Castings has inhouse metal material testing to ensure the composition of the metal we use for our castings meets the specifications and standards set by our customers. These metal material testing methods consist primarily of chemical analysis testing, and metallography.

Chemical analysis is the cornerstone of foundry metallurgy, and therefore Niagara Investment Castings utilizes state-of-the-art spectroscopy to analyze both ferrous and non-ferrous alloys for chemical content for EVERY heat of metal produced. Certified universal standards are used to verify every analysis.

In instances where chemical analysis requirements are even greater than we can perform inhouse with our spectroscopy equipment, sample preparation (by milling or drilling) and a full range of “wet analysis” testing is performed according to the strictest specifications at our accredited 3rd party laboratory.

Our Metallography metallurgical services include cross-sectioning, mounting & polishing specimens for microscopic examination including grain structure, grain size, inclusion rating, depth of carburization, case depth and more. This is useful to verify not only effective heat treatment, but to evaluate the internal integrity of the casting itself.

Tensile (Tension) Testing of Metals

One of the most common physical tests performed at Niagara Investment Castings is tension testing of metals. Tension testing is carried out to test the tensile properties of the metals we produce.

Tensile Testing, or Tension Testing, is used to determine the behaviour of the metal when it is being placed under a “pulling” load or stress. Tensile testing will measure yield strength, proof strength and ultimate tensile strength. Niagara Investment Castings has the ability to test at elevated temperatures as well as sub zero temperatures.

The most common standards that we test to are as follows:

- Elevated Temperature Tension Tests ASTM E21

- Standard Tension Testing per ASTM E8, ASTM A370, and ASTM B557

- Strain Hardening Exponent (n Value) ASTM E646 and Plastic Strain Ratio (r Value) ASTM E517

- Stress Rupture Test (to 2000°F) machine -ASTM E139 and ASTM E292

Hardness Testing of Investment Castings

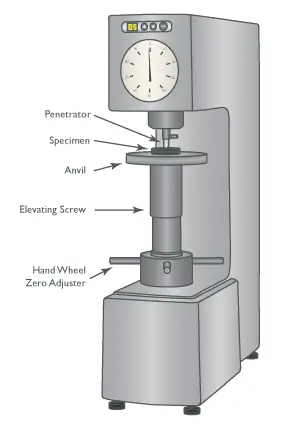

There are several ways to verify the hardness of an investment casting both pre and post heat treatment. Our hardness testing service consists of checking castings using Rockwell testing or Brinell testing.

Rockwell testing consists of a series of indenters usually made from diamond in a cone shape, or a hardened steel or carbide ball, forced into a sample of the metal, all done on a fixed anvil. These are forced into the surface of the metal casting by a fixed force, and the depth of the penetration of the indenter is measured and used to calculate the hardness of the metal, since the harder it is, the less it can be penetrated.

A Rockwell testing machine is pictured above, and is a fragile instrument usually limited to the confines of a laboratory to maintain a clean and constant temperature environment.

Brinell hardness testing is a hardness testing method typically used on softer metals than the Rockwell test is used for. The test measures the resistance of a material to indentation by a hard, spherical indenter (typically a tungsten carbide ball) which is driven into the material’s surface with a specific force and for a predetermined time. The size of the resulting indentation is then measured and this measurement is used to calculate the Brinell hardness number (HB).

The typical standards for these are tests are :

- Brinell Hardness per ASTM E10

- Rockwell Hardness per ASTM E18

Charpy Impact Testing of Investment Castings

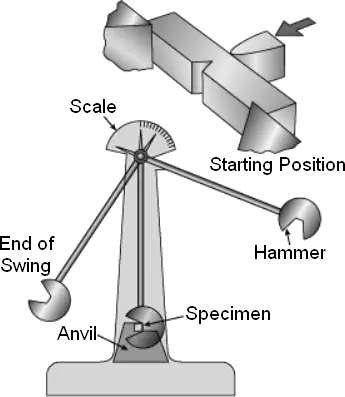

There are some castings which require testing of their ductility, or shear strength, and these metals are tested for that using the Charpy Impact Test. The test is also known as the Charpy V-Notch test.

The test is a standardized method used to determine the amount of energy absorbed by a material during fracture, which indicates its toughness. Performed at BOTH room temperature, or more commonly, at sub zero temperatures, the test uses a swinging hammer to measure a metal samples resistance to fracture under sudden impact by the hammer, falling from a set height. This test is particularly useful for identifying the ductile-to-brittle transition temperature of a material. The common types of Charpy tests are as follows :

- Charpy V-notch Impact Testing per ASTM E23

- Rectangular or Round Izod Testing per ASTM E23, BAEP 9004

Radiographic Testing of Investment Castings

The most common “Non Destructive Tests” (NDT) for investment castings are radiography (xray) and liquid penetrant testing (LPI).

Radiography is a non-destructive method of inspecting materials for hidden flaws by using the ability of short wavelength electromagnetic radiation (high energy photons) to penetrate various materials. Either an X-ray machine or a radioactive source can be used as a source of photons.

The major objective of radiographic testing of castings is the disclosure of defects that adversely affect the strength of the product. Castings are a product form that often receive radiographic inspection since many of the defects produced by the casting process are volumetric in nature and are thus relatively easy to detect with this method. These discontinuities are related to casting process deficiencies, which enable the professionals at NIC to address suitable corrective measures.

Since different types and sizes of defects have different effects of the performance of the casting, it is important that the customer knows what level of acceptance he requires to enable us to identify the type and size of the defects and how they may or may not affect the end use of the casting.

Niagara Investment Castings is capable of manufacturing our castings to virtually any radiographic level of quality.

Dye Penetrant Testing of Investment Castings

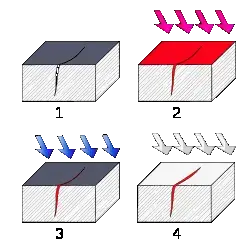

A liquid penetrant inspection (LPI) test is a widely applied and low-cost “Non destructive test” or inspection method used to locate surface-breaking defects in all investment castings. LPI is used to detect casting defects, cracks, and leaks in new products, and can be also used to locate fatigue cracks on in-service components.

The test is essentially a series of steps including the application of a penetrent, or dye, to the surface of the casting, allowing it to be pulled into any linear defects by capillary action, washing off of the excess penetrent, and a final application of a white developer, or blotter, to draw the dye back out to indicate the presence of the defect(s).

- Section of material with a surface-breaking crack that is not visible to the naked eye.

- A penetrant is applied to the surface. The penetrant can be a simple dye (usually red) or a fluorescent dye that can indicate extremely fine details using black light.

- Excess penetrant is removed.

- Developer is applied, rendering the crack visible either to the naked eye or under black light if fluorescent dye was used.

Macroscopic Examination Testing of Investment Castings

With just the naked eye, a visual examination of the casting can be used to determine some test results, including :

- Particle Count for cleanliness

- Weld Evaluation per ASME IX, CSA W47.1, AWS D1.1, and EN 1321

- Visual Evaluation and photos

Microscopic Examination Testing of Investment Castings

The use of “microscopic” analysis of a casting is not as common as most of these other tests, however there can be very useful information that can only be obtained using these examination techniques.

Microstructure testing is essentially using a microscope, or a version of a machine that looks closer than the human eye can, to examine the microscopic features of metals, revealing details like grain size, grain boundaries, and the arrangement of different phases within the material. This evaluation of the microstructure allows us to gain insights into a metal casting’s mechanical properties, its response to post-casting processing (heat treatment, welding), and its vulnerability for any potential failures.

Microscopic examination testing can include:

- Microstructure

- Grain Size, including McQuaid Ehn method per ASTM E112

- Phase analysis

- Micro cleanliness / Inclusion Rating per ASTM E45 Methods

- Volume Percent Determination per ASTM E1245

- Plating Thickness per ASTM E3

- Microhardness Testing (Vickers or Knoop 50g to 1000g) per ASTM E384

Conclusion

The ability to offer our clients full material testing and certification services ensures we are providing the exact combination of the desired chemistry makeup to meet the physical properties in your investment cast components

This is where the experts at Niagara Investment Castings can make choosing the right testing and certifications easy for you. Our metallurgical expertise is yours to tap into when you partner with NIC for your casting requirements, whether for testing, or anything related to the investment casting process.

Simply start by visiting our Request for Quotation page, and let us know how we can be of service.