Almost without exception, there is one common theme when it comes to perceived problems with using metal investment castings, and that is the concern that the castings will contain some form of porosity which could render the cast component unsuitable for the application in question.

While advancements such as computerized simulations of casting solidification have provided metal casters with tools to help minimize casting porosity, some type of porosity can still exist even in the most carefully designed castings, whether those are investment castings, sand-molded castings, or permanent mold castings.

It is widely accepted that depending on where the porosity is located in the casting, certain levels of porosity are in fact standard in many commercial applications, while in other applications where ultimate strength of the casting is paramount, zero porosity must be achieved.

What is Porosity in Castings?

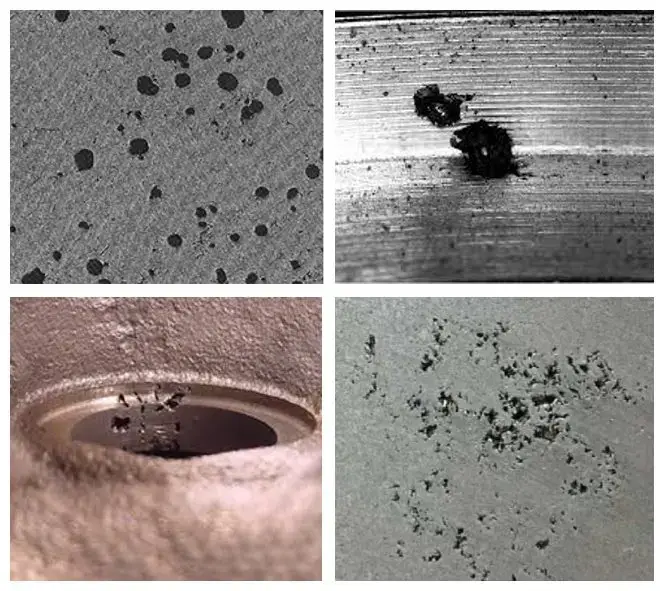

Porosity is often used to describe any void, hole, or discontinuity found in a casting. But the morphology of pores in terms of their size, shape, surface constituents, location, and frequency are essential in defining the specific defect, determining its cause and analyzing the extent to which it will adversely affect the casting’s properties or functionality.

This article will discuss the common types of porosity in castings, how to find it, how to minimize it, and how to deal with it when zero porosity castings are required.

Casting Porosity Acceptance Criteria

It is common for many foundries to produce a casting with porosity periodically. Yet, it is never acceptable to simply accept it will permanently be present when the proper foundry methodology is ALWAYS to apply the proper techniques to minimize or eliminate it. Certainly, we never want to settle for a less than optimum integrity in any cast product we manufacture; however, the most important point is that we need to stress is the presence of some degree of porosity does not necessarily mean the cast product is not acceptable for its intended application. In fact, often the design of the casting itself can be a key contributor to why porosity may form in the casting, and just as often, it will have virtually zero impact on the product’s functionality.

Of course, there are also many times when any porosity in a casting cannot be tolerated, and therefore it must be detected and removed and the casting certified to be 100% sound in terms of integrity.

Casting Porosity Causes

Cast metal will generally exhibit voids due to either shrinkage-related porosity, gas bubble porosity (or back pressure as it is sometimes referred to) or foreign inclusions such as non-metallic slags, dirt, or bits of refractory. Each of these is discussed in greater detail as follows.

Shrinkage

Since liquid (melted) metal is volumetrically greater than the same weight of metal in a solid form, and since the casting process involves filling a mold with this liquid metal, there must be allowances for the metal to be fed into the casting as it solidifies and shrinks. This is accomplished by placing ingates around a casting, generally into the heaviest sections of the casting, since those will be the last to solidify; hence, feeding the molten metal to the thinner sections occurs first.

Gate placement is a specialized engineering function, and with improvements in computer simulations, the foundry is able to minimize most instances of shrinkage by working with our clients to come up with the most suitable geometric designs to allow us to then apply the most optimum feeding of the casting.

Even then, there are times when a casting has so many thick sections adjacent to each other that gating into every heavy section is impossible.

Many times, there will be very small pockets of shrinkage in a casting that cannot be eliminated, and therefore, various levels of acceptance criteria exist, depending on the requirements of the casting.

Gross shrinkage discontinuities in a casting are almost always considered detrimental however, gross defects should be able to be minimized and most all cases through design modifications combined with the most effective gating (or feeding) locations.

For more information on casting shrinkage and why it happens, click here to read our blog.

Gas Bubbles

Certain alloys produced by NIC have the ability to dissolve large volumes of nitrogen, oxygen, or hydrogen gases when in their molten state. At the same time, these alloys will not often retain these gases in their solid state. As a result, during the casting process, these gases will drop out of solution and will form small bubbles or pockets of bubbles as the casting solidifies, locking them into the matrix.

Most often these voids appear as smooth round holes and are most always located in the heaviest or thickest section of the casting, in the last metal to solidify. This condition is controlled through the use of degassing agents added to the metal. These agents will react with the dissolved gas in formed solid slags, which then can be skimmed or filtered from the molten metal prior to pouring.

This technique is effective, however, it will not always render a 100 percent successful heat of metal, and some bubbles can still form as molten metal will continue reacting with the atmosphere, even after degassing. Again, most specifications will therefore allow for some degree of this type of void in the casting.

Inclusions

Generally, the easiest to understand of all casting defects, inclusions are simply small bits of non-metallic materials that find their way into the casting. These can be small bits of refractory from the furnace or ladle, small pieces of the ceramic shell from the mold itself, or even small bits of the slag formed from the degassing agents. From the foundry’s perspective, good practices, clean molds, and the use of ceramic filters will keep non-metallic conclusions to a minimum, however there is no way to fully prevent the small bits from being carried in the metal stream and into the casting.

While all three categories of porosity defects may appear to be detrimental to a castings internal integrity, the fact is that the typical small voids associated with castings can have a wide range of impact on the functionality, ranging from absolutely no detriment, up to being extremely detrimental if the voids are located in highly stressed areas of the casting.

How to Avoid Casting Porosity in Castings

The process controls involved in ensuring a casting is as free as possible from these various forms of porosity are well understood by experienced foundrymen. Utilization of modern solidification prediction software, the use of the correct degassing agents for the alloy being poured, and use of metal filters and proper sprues when it comes to the transfer of metal from furnaces and ladles into the mold, are some of the tools available to us.

With good foundry practice, porosity in a casting can be minimized to an acceptable limit. However, it is always important to keep in mind that porosities in castings can rarely be completely eliminated due to the nature of flowing extremely hot and chemically active metal into a mold.

The metal purges gases out of solution as it cools from liquid to solid, which can also foster the formation of non-metallic matter and carry bits of the refractories used to melt it. The entirety of the time, it is being transferred from a melting furnace into the mold. Even if the metal is perfectly clean, once it is in the mold and the metal starts to cool, it shrinks in volume, which can lead to shrinkage voids.

The question of how to avoid porosity in castings in one that comes with the best of intentions; however, the risk of some level of porosity being present is one of the compromises a designer must make when specifying castings. That said, every application for a cast component is different, hence the many acceptance standards using NDT or non-destructive testing, which can be applied to determine suitable conformity for the casting application.

There is no one set of acceptable criteria when it comes to casting integrity, which only adds to the difficulty in our customers deciding what should be considered acceptable and what is not. In fact, there is a wide range possible testing, acceptance criteria, and possible outcomes when it comes to casting integrity. This is because metal casting comes with an inherent probability of various types of voids, inclusions, and other discontinuities in the castings, all characteristics not generally seen when comparing with other processes such as rolled or extruded, metal products, forgings, etc.

Subsurface Porosity in Castings

Most investment castings are produced at what is called a commercial level casting, where a degree of internal porosity should be expected due to geometric restrictions and in those cases where the porosity has no detrimental impact. However, in cases where any degree of porosity can impact the castings application, how to deal with it, and how to find it, become important considerations.

Porosities can be classed as “subsurface” porosity, meaning hidden in the casting and not obvious from the surface, and “surface” porosity, those that are open to the surface, and that can include fractures or cracking of the metal matrix.

Testing for Subsurface Porosity

There are several acceptable practises in industry for determining subsurface porosities, or discontinuities in general in castings. Those include radiography inspection, and ultrasound testing. These testing methods allow for the user to “see” porosities, or other discontinuities, which are hidden inside of the casting, and not visible to the naked eye.

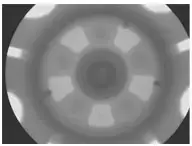

Radiography of a casting is the best non-destructive inspection method for detecting internal defects of castings. In this method, a casting is exposed to radiation from an X-ray tube. The casting absorbs part of the radiation, and the remaining portion of the radiation exposes the radiographic film.

There are a multitude of radiography standards that are specified when it comes to how much porosity is acceptable in the casting. A Class 1 casting will be the highest level, with virtually zero porosity being permitted. However, anything other than Class 1 will allow a gradually increasing amount of porosity in the casting to be present.

Ultrasonic testing (UT) of castings uses high-frequency sound waves to inspect for defects. A transducer emits high-frequency sound waves into the casting, and porosity defects disrupt the flow of these sound waves back to the transducer, allowing the operator to determine the size and location of internal porosity. Once again, classification of the amount of porosity found will determine whether or not the casting passes or fails the examination based on the standard being specified for the casting.

Testing for Surface Porosity

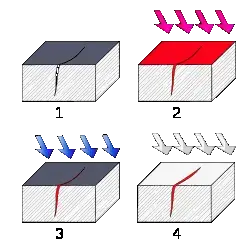

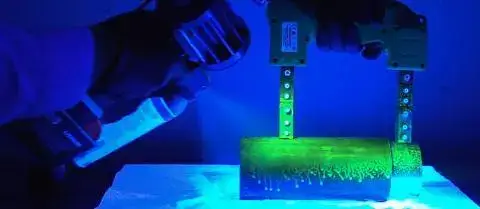

There are two main acceptable practices in industry for determining surface porosities: Liquid Penetrant Inspection, both visual dye or fluorescent, and Magnetic Particle Inspection.

Liquid penetrant testing is a highly utilized method to check for discontinuities in a casting which are open to the surface. Dye, either visible or fluorescent, is applied to the surface of the casting and is drawn into any openings through capillary action. The castings is washed clean of any remaining die, and then a developer powder is applied to the surface to drawn back out any dye, revealing the presence of surface discontinuities.

Magnetic particle inspection focuses on detecting casting defects open to the surface, such as cracks, seams, inclusions, porosity, etc. An electrical “inducer” device is used to impart a magnetic field in the investment casting, and a powder consisting of fine iron magnetic particles is applied. The particles will align in various patterns to expose invisible defects, without harming the part in any way.

In most cases, any surface discontinuity discovered by a surface test is considered unacceptable.

“Zero Porosity” Castings

The term “Zero Porosity” in castings in somewhat misleading, as there will inevitably always be some sort of porosity that will find its way into a cast matrix due to the inherent nature of the casting process. However, when the possibility of having porosity can lead to nonconformance of the cast component in its intended application, such as a pressure retaining component, or ultra high strength component, there are post-casting techniques which can be utilized to maximize the density of the investment casting. These are Hipping and Impregnation.’

HIPPING Process (Hot Isostatic Processing)

Hot Isostatic Pressing (HIP) is a manufacturing process that uses high temperature and isostatic pressure to densify materials like metals, ceramics, and composites. This process significantly enhances material properties by reducing porosity and increasing density.

The HIP process compresses materials by applying high temperature of several hundreds to 2000 °C and isostatic pressure of several tens to 200MPa at the same time. Argon is the most commonly used pressure medium.

This process can be used with metal investment castings and is a valuable manufacturing process that enhances the properties of various materials by increasing their density and reducing porosity. This leads to improved mechanical performance, durability, and overall quality of manufactured parts.

Impregnation

Impregnation is another commonly used method to get rid of porosity in cast parts. It is also called porosity sealing or porous metal sealing. The metal impregnation technique was first introduced in 1940 and the method has been improving since then. Impregnation is a specialised treatment carried out by penetrating reinforcing acrylic resins into the porous structure of the metal.

The vacuum or metal impregnation technique can seal both micro and macro porosity but it doesn’t change the functional or mechanical properties of a part.

When multiple pores connect with each other, the path created is called a leak path. Vacuum impregnation can seal any size of pores and leak paths. If a fully enclosed porosity somehow connects with a blind or a through porosity and makes a leak path, then vacuum impregnation can seal it.

Contact Niagara Investment Castings for More Information

At Niagara Investment Castings, we are experts in the unique world of investment casting. We can work with you to advise on the potential risks and impact of porosity on your specific application, and the economics of scale should your casting design require minimal or zero porosity.

We will recommend the various testing techniques to certify the casting to the required level of acceptance, and work with you to revise or modify any aspect of the casting to permit us to provide the most optimum and efficient feeding of the casting to minimize the chances of any of the various types of porosities seen with investment castings.