Precision Investment Casting Manufacturing

Niagara Investment Castings is a Canadian full service manufacturer of high quality investment castings with over 50 years experience in manufacturing a full range of cast components, from simple to complex, for a wide variety of end users and industries.

- Precision investment castings from ounces to 200 lbs in weight.

- Castings are produced in most engineering materials, including low- and high-carbon steels, stainless steels, tool steels, nickel-based alloys, cobalt-based alloys, and copper-based alloys.

- From simple parts to highly complex castings

- From thin-walled castings to heavy sections

- Superior surface finish compared to other casting techniques

- Certified welding

Automation and Efficiencies

Niagara Investment Castings believes that investments in the best technologies available for our manufacturing facility will reward our clients with the best quality at the lowest prices.

- Automated wax injection for large volume production requirements.

- State-of-the-art water blast shell removal.

- Robotic shell building is used to ensure the repeatability of shell quality and consistency between castings.

- Ergonomical material handling throughout the plant.

- Effective flow of product through the plant to minimize downtime and maximize efficiencies.

Rapid Prototype Castings

When small-volume production runs are cost-sensitive or receiving first-off samples BEFORE tooling is made is beneficial to our Clients, Niagara Investment Castings offers 3D-printed plastic patterns to utilize in the manufacturing of our investment castings, saving the time and cost of hard tooling used for larger production runs.

- In-house 3D “printed plastic pattern” technology.

- Multiple printers to produce multiple patterns at the same time.

- Filament printing and SLA available

Heat Treatment

Heat treatment of metal alloys is a key step in ensuring the properties of the castings we manufacture meet the stringent requirements set out by both industry standards and our clients. Niagara Investment Castings takes on this crucial processing step of ensuring the proper heat treatment as part of our total service commitment to our clients.

- We offer a full range of heat treatment processing, including annealing, solution annealing, normalizing, quench and temper hardening, case hardening, nitriding, and age hardening.

- Fast turnaround by our verified industry partners

- Full range of certifications and hardness testing available

Machining and Finishing

Let the professionals at Niagara Investment Castings look after all of the finishing requirements for your castings. Machining, plating, electropolishing, and more are available through our network of subcontractors to provide you with a single source for your cast components.

- Full machining services for fully “turn key” product support.

- Full range of surface treatments available including passivation, plating, painting, or polishing.

- In-house surface preparations including shot blast, grit blast, sand blast, and glass beading.

- Straightening, cold and hot press.

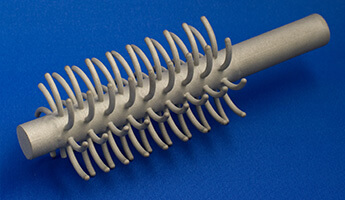

Internal Ceramic Coring and Core Removal

The internal detail that is possible with investment casting requires the use of ceramic preformed cores for many critical applications. Niagara Investment casting utilizes ceramic coring regularly for our wide range of customers and industries where this technique is the only cost effective way to get this level of detail. After the pour, our inhouse Kolene salt bath ceramic removal technology cleans the ceramic out of the tightest sections of your castings with ease.

- Ceramic coring for complex internal detail.

- Soluble wax coring

- Complex and challenging internal casting designs and detail.

Testing and Certification

Niagara Investment Castings provides material certifications to ensure our produced castings meet all specifications, strength requirements, and internal soundness that our customers insist on.

- A full range of NDT testing capabilities, including radiography, magnetic particle inspection, liquid penetrant inspection, and ultrasound.

- Comprehensive metals testing capabilities, including chemical analysis, mechanical testing, charpy testing, metallography, grain size analysis, and corrosion testing.

Quality Assurance System

Quality is key, and Niagara Investment Castings has registered quality assurance systems in place throughout the manufacturing process to ensure every detail is verified to meet the exacting and demanding requirements of our customers.

- All manufacturing is to ISO 9001 Quality System.

- ISO14001 Environmental System certified.

- Certified to the European Pressure Standard PED 4.3.

- MRP system plant-wide for effective and efficient data sharing and retrieval.

See our list of quality assurance certificates.

Engineering and Metallurgical Assistance

Count on the experience and professionalism of our engineering team to deliver not only high quality investment castings, but also the expertise our customers need to help them make the right decisions when it comes to designing their cast components.

- Computerized “Solidification Modelling” to ensure sound castings prior to the job going to the shop floor for production.

- Hands-on assistance with clients’ designs utilizing SolidWorks three-dimensional drawing capabilities.

- Metallurgical assistance with alloy selection

- Proper shrinkage allowance assistance

Complementary Associate Companies

We are proud to be a member of the Zynik Group of Companies, offering our customers a wide range of products and services through our sister companies. Through our partnerships with this dynamic group of manufacturers, we are always happy to assist in any way we can.

Through our diverse family of sister companies, we offer “one-stop” sourcing for other complementary cast products, including sand-cast gray and ductile iron, sand-cast steel and stainless steel, and aluminum die castings.